Blow Molding

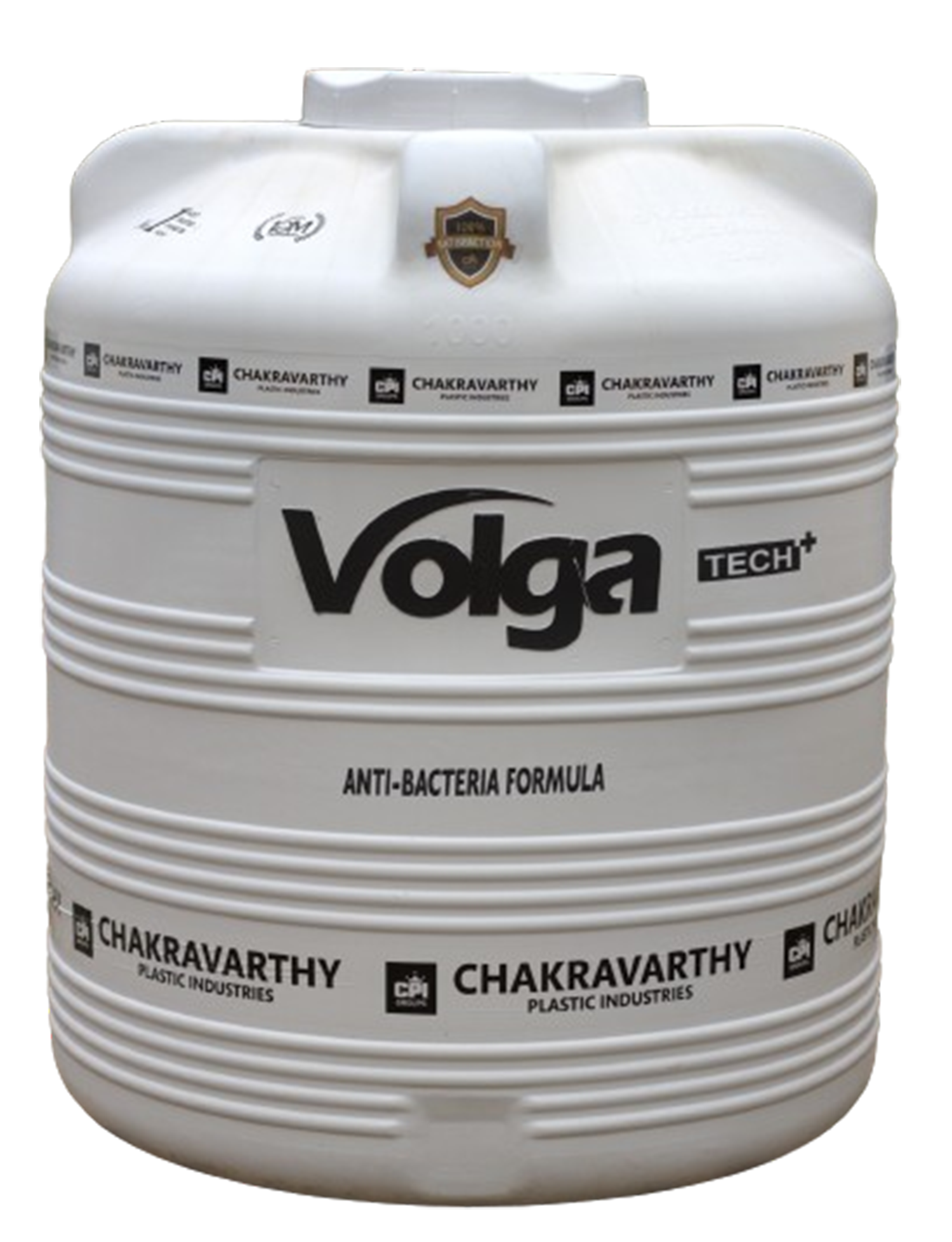

Water Tanks

Blow molding is a manufacturing process for creating hollow plastic parts or tanks.The blow molding process begins with loading the raw material in to different hoppers for the particular layers (Usually 2 and 3 Layers are familiar).

Then the raw material is melted and layers are formed according to the layers which we have programmed. Melted plastic layers are sent down through a die core into the separated molds. The molds are closed and compressed air will be released and then the raw material formation is applied to the mold surface.