BLOW TECH

Blow molding is a manufacturing process for creating hollow plastic parts or tanks. The blow molding process begins with loading the raw material into different hoppers for the particular layers (Usually 2 and 3 layers are familiar). Then the raw material is melted, and layers are formed according to the layers which we have programmed. Melted plastic layers are sent down through a die core into the separated molds. The molds are closed, and compressed air will be released, then the raw material formation is applied to the mold surface. Cooling water is passed to reduce the temperature and to harden the plastic, and then the mold is opened up to fetch the tank.

Features

Size - Liters

500 750 1000

Colour

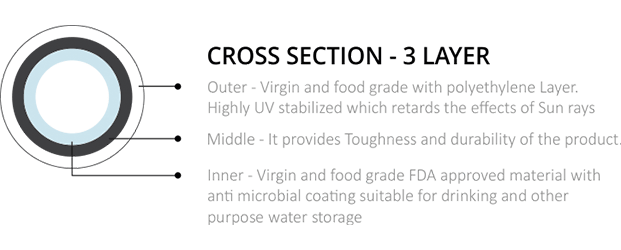

TANK SPECIFICATION